Laser Cutting Systems Z O.o

Next, press and hold the main switch. This will turn on main power. Turn on the key switch to the control panel. This is machine specific and not applicable to all lasers. After startup, the system can start to quote if all covers that have safety circuit breakers are closed. After turning on the machine the table will move all-the-way down while the pro laser head (located in upper left corner) moves to zero. When the LED light flashes slowly and steadily, it is safe to say that the machine has completed its reference process.

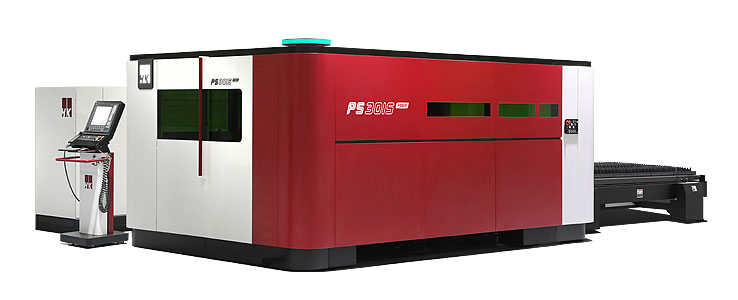

The laser's interlocked metal enclosure carries with it a class 2 safety rating, which allows for safe use in any workshop, home, or office.